Small to medium sized walls are constructed with the proper batter and engineering for the material used. Many of our customers have used E. P. Henry wall stones, but we also can use Imperial, Techo-Bloc, Cambridge, Belgard, Anchor, Hanover, Rinox, CST, Allen Block or any other brand of wall stones. Installation is the same for all of the different brands. Segmental Retaining Walls can be used for a long-lasting and nicely textured wall. Shown here is construction of a wall 3½ -ft. high above grade.

For the last few years new styles and colors of wall stones have been added each year. Check out manufacturer’s web sites for more up to date information. To order the current years catalog see E. P. Henry, Techo-Bloc or other paver companies web sites.

This page is here to illustrate how we construct our wall and should not be used as a ‘how to’ guide for wall construction. Many variables can affect how a wall performs such as slope at the top and bottom of the wall, surcharge or weight at the top of the wall (a parking lot at the top of a wall will add a lot of pressure), type of soil, water drainage behind the wall and construction in a flood plain are all variables that may need an engineer to resolve. Walls over 4-ft. in height should also have engineering plans.

Wall Construction Photos

- Elevations are taken and the height of the wall is determined. Walls over 4-ft. require an engineer to insure proper construction. Tiered walls require a distance at least twice the height of the lower wall between the wall to be considered as separate walls. Planning for the fence at the top of the wall should be considered at this time.

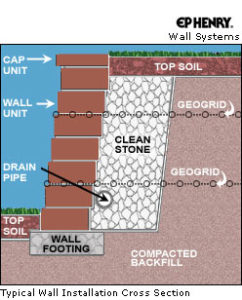

- Trench for wall is excavated at least 2-ft. wide and deep enough to install a 6-in. modified stone base and to bury one entire layer of wall stones. After excavation subsoil is compacted and modified stone is installed and compacted in two layers. Wall stones are installed level and filled with clean crushed stone.

- Perforated pipe is installed behind the wall for drainage, and should have an outlet at least every 40-ft. Soil from excavation can be set aside if suitable. As the crushed stone is installed behind the wall; the backfill is installed beyond that and compacted.

- Upper layers are installed according to manufacturers instructions to insure proper batter (or slope back into the hill). Some wall stones require pins and others are manufactured with a lip on the back to give the proper setback.

- All wall stones are filled with clean crushed stone and 1-ft. of stone is also installed behind the wall for drainage. Taller walls require geogrid to reinforce the wall and help tie the wall into the hill.

- Length of geogrid, number of layers needed and placement of layers will be specified by an engineer for wall over 4-ft. high. Continue upper layers; pins for this type of wall are shown here. Fill crushed stone inside and 1-ft. behind wall.

- Finished wall shown with drainage outlet through the wall. Two layers of wall stone were buried for this wall because of the toe slope away at the bottom of the wall. Wall here is capped with stone wall select caps.

- Backfill is installed; soil is install for the entire top one foot behind the wall. Planning for the fence at the top of the wall should be thought out before construction to prevent damage to the wall and simplify installation of the fence.

- Construction detail from the E.P. Henry Website

Shown here is construction of a wall 3½ -ft. high above grade.